Third-party logistics (3PL) fulfillment centers operate under constant pressure: high order volumes, short shipping windows, and a wide variety of package sizes and weights. While automation and software often take center stage, one critical element is frequently overlooked—the packing table.

In reality, packing tables are the physical backbone of fulfillment operations. Their design directly affects packing speed, error rates, worker fatigue, and even injury risk. This article explores what defines a truly heavy-duty packing table for 3PL environments and how to evaluate options using both industry best practices and safety principles recognized by authoritative organizations.

Why Packing Tables Matter in 3PL Fulfillment Centers

Unlike single-brand warehouses, 3PL fulfillment centers handle constantly changing SKUs, carton sizes, and order profiles. A packing station must support:

- High-frequency, repetitive packing tasks

- Wide variation in package weight and dimensions

- Continuous multi-shift operation

- Fast onboarding of seasonal or temporary labor

Industry research and warehouse design guides consistently show that poorly designed packing stations lead to bottlenecks, higher error rates, and increased physical strain. From an operational perspective, a packing table is not furniture—it is production equipment.

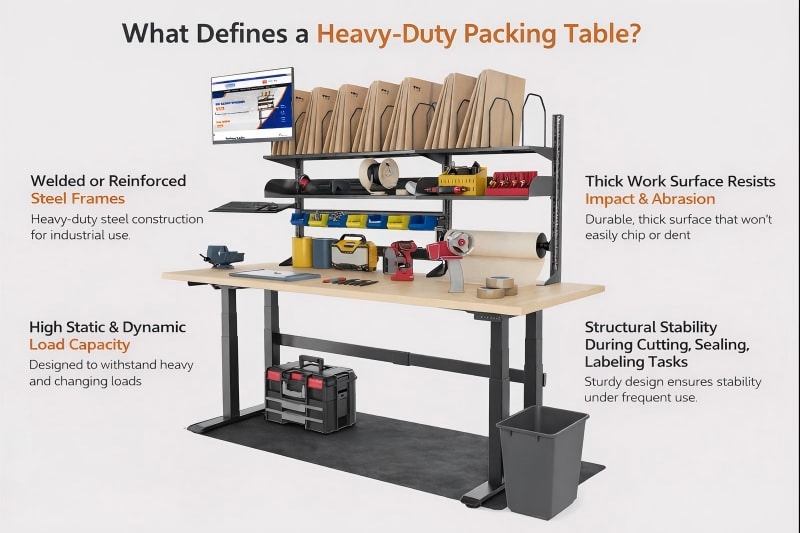

What Defines a Heavy-Duty Packing Table?

A heavy-duty packing table is engineered for industrial workloads, not light assembly or office-style use. Compared with standard packing tables, heavy-duty models typically feature:

- Welded or reinforced steel frames

- High static and dynamic load capacity

- Thick work surfaces designed to resist impact and abrasion

- Structural stability during cutting, sealing, and labeling tasks

In high-volume 3PL environments, tables that flex, wobble, or degrade quickly become operational risks. Stability directly affects packing accuracy, labeling quality, and worker confidence.

--shopstart--{"id":170325,"link":170325,"name":"Premium Extremely Stable Electric Height Adjustable Workbench WB2R","shortName":"Electric Workbench","url":"https://s3.springbeetle.eu/dev-de-s3-flexispot/commodity/item/1028_file_普通产品新年_WB2RB-72RB_20251229_EKLCh2sK.png","itemFootMarkType":"NONE","itemFootMarkInput":""}--shopend----shopstart--{"id":172224,"link":172224,"name":"All-in-one Accessories Set 52\" Version","shortName":"All-in-one Set","url":"//s3.springbeetle.com/prod-us-bucket/trantor/attachments/USFD/主图2_PEG003.png","itemFootMarkType":"NONE"}--shopend--

Key Factors to Look For in 3PL Packing Tables

1. Load Capacity and Structural Stability

Heavy parcels, bulk orders, and consolidated shipments place continuous stress on packing surfaces. Industry blogs consistently recommend selecting packing tables with load ratings that exceed typical carton weights to avoid long-term structural fatigue.

From a safety standpoint, the Occupational Safety and Health Administration (OSHA) emphasizes that unstable or inadequately designed work surfaces can contribute to unsafe working postures and increase injury risk during material handling tasks.

2. Ergonomic Design and Adjustable Working Height

Packing is a highly repetitive activity. Over time, excessive bending, reaching, or awkward wrist positions can lead to musculoskeletal disorders (MSDs). OSHA and the National Institute for Occupational Safety and Health (NIOSH) both highlight workstation height and reach zones as key ergonomic risk factors in warehousing.

Adjustable-height packing tables—manual or electric—allow work surfaces to align with the worker’s task and body dimensions. This flexibility helps:

- Reduce lower-back strain

- Minimize shoulder and wrist fatigue

- Support both seated and standing workflows

For 3PL operations with diverse labor profiles and rotating tasks, adjustability is not a luxury—it is a practical risk-reduction tool.

3. Workflow Efficiency and Layout Compatibility

High-performing fulfillment centers design packing stations as part of a larger workflow, not as isolated tables. Industry best practices recommend aligning packing tables with:

- Conveyor discharge points

- Carton storage and dunnage zones

- Label printers, scanners, and scales

Well-designed packing tables reduce unnecessary walking, reaching, and twisting—principles that align closely with OSHA’s ergonomic hazard control guidance.

4. Storage, Organization, and Modularity

Cluttered packing stations slow down fulfillment and increase error rates. Many industrial packing tables integrate:

- Lower shelves for cartons or finished packages

- Overhead racks for packing materials

- Mounting options for monitors, printers, and tool holders

Modular designs allow 3PL operators to reconfigure stations as client requirements change—an essential capability in multi-tenant fulfillment environments.

5. Durability Over Multi-Shift Operation

Unlike light-duty workbenches, packing tables in 3PL centers often run 16–24 hours per day. Long-term durability affects not only replacement costs but also uptime and safety consistency.

From a compliance perspective, maintaining equipment in good condition aligns with OSHA’s general duty requirements to provide a safe workplace.

--shopstart--{"id":172197,"link":172197,"name":"72\" x 72\" L-Shaped Industrial Workstation with Storage","shortName":"L-shaped Workstation WB5LB Set","url":"https://s3.springbeetle.eu/dev-de-s3-flexispot/commodity/item/1028_file_20251229-181828_20251229_Ai4b0NFZ.png","itemFootMarkType":"NONE"}--shopend-- --shopstart--{"id":170324,"link":170324,"name":"Dual Monitor Stand WMA8D Support Max 32 Inch, 4.4 - 19.8 Lbs Screen","shortName":"Monitor Stand WMA8D","url":"https://s3.springbeetle.eu/dev-de-s3-flexispot/commodity/item/1028_file_主图2_DLB851D2.png","itemFootMarkType":"NONE"}--shopend--

Types of Heavy-Duty Packing Tables Used in 3PL Operations

- Fixed Heavy-Duty Packing Tables: Ideal for standardized, high-volume packing lines.

- Height-Adjustable Packing Tables: Support ergonomic variability and mixed workflows.

- Mobile Heavy-Duty Packing Tables: Useful for flexible layouts or seasonal reconfiguration.

- Integrated Packing Stations: Combine table, storage, and technology into a single workstation.

The right choice depends on order profiles, labor strategy, and space constraints—but heavy-duty construction remains the common requirement.

How the Right Packing Table Improves 3PL Performance

When packing tables are selected with durability, ergonomics, and workflow in mind, fulfillment centers often see:

- Higher packing throughput

- Lower error and rework rates

- Reduced worker fatigue and turnover

- Improved safety culture and compliance alignment

These improvements are not theoretical. They reflect the same principles promoted by industry design guides and reinforced by OSHA and NIOSH ergonomic research.

Final Thoughts

In 3PL fulfillment centers, packing tables are mission-critical infrastructure. Choosing heavy-duty, ergonomically informed designs helps align operational efficiency with worker safety—two goals that are increasingly inseparable.

By evaluating load capacity, adjustability, layout compatibility, and long-term durability, fulfillment leaders can build packing stations that support both current demand and future growth.