Ergonomic Workbench Selection for Long-Shift Warehouse Operations

In modern warehouse operations, productivity is no longer driven solely by automation and software. For teams working 8 to 12-hour shifts, the physical workstation plays a critical role in worker health, efficiency, and long-term performance. Choosing the right ergonomic workbench is no longer optional—it is a strategic operational decision.

This guide answers the most common questions warehouse managers, operations leaders, and procurement teams ask when selecting ergonomic workbenches for long-shift environments.

Why Do Long Shifts Require a Different Type of Workbench?

A workbench that performs well for short tasks often fails under long-shift conditions. During extended warehouse operations, workers experience cumulative fatigue caused by:

- Prolonged standing or static posture

- Repeated reaching, bending, and twisting

- Inconsistent working heights across tasks

Over time, these factors increase error rates, slow down throughput, and raise the risk of musculoskeletal injuries. An ergonomic workbench designed for long shifts helps maintain neutral posture and reduces physical strain throughout the entire workday—not just during peak activity.

What Is an Ergonomic Workbench in Warehouse Operations?

In a warehouse context, an ergonomic workbench is not defined by comfort alone. It is a workstation designed to adapt to both the worker and the task, especially during long operational shifts.

Key ergonomic principles include:

- Height adjustability to support different workers and tasks

- Neutral working posture that minimizes shoulder, back, and wrist strain

- Optimized reach zones to avoid excessive bending or stretching

- Stable, heavy-duty construction to reduce vibration and micro-fatigue

In long-shift warehouse operations, ergonomics is about consistency—helping workers maintain safe posture hour after hour.

Why Are Height-Adjustable Workbenches Important for Long Shifts?

One of the most common questions is whether height-adjustable workbenches are truly necessary. For long-shift warehouse operations, the answer is yes.

Adjustable-height workbenches allow teams to:

- Alternate between standing and seated tasks

- Accommodate different worker heights on shared stations

- Maintain proper elbow and wrist positioning across task types

Even small height mismatches—multiplied over thousands of repetitions—can lead to fatigue and injury. Many warehouses address this by using industrial adjustable workbenches that support both manual and electric height adjustment, depending on task frequency.

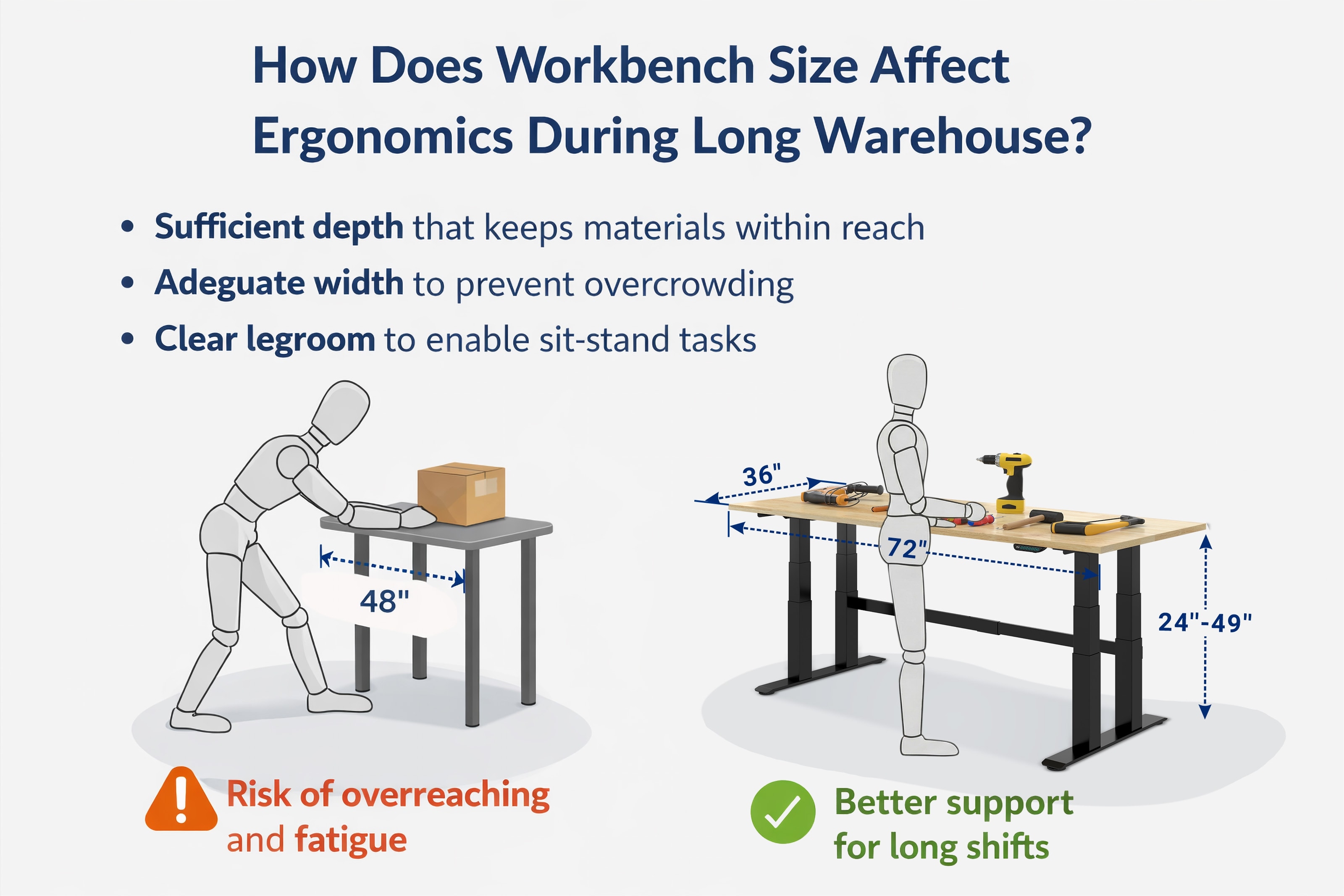

How Does Workbench Size Affect Ergonomics During Long Warehouse Shifts?

Workbench dimensions are often overlooked, yet they play a major ergonomic role in long-shift environments.

An ergonomic workbench for warehouse operations should provide:

- Sufficient depth to keep materials within safe reach zones

- Enough width to prevent overcrowding of tools and packaging materials

- Clear legroom for seated or sit-stand tasks

Overreaching during packing, assembly, or inspection tasks increases shoulder fatigue and slows down operations. Heavy-duty workbenches with standardized industrial dimensions—such as 72” × 36” configurations—are commonly used to balance space efficiency with ergonomic reach.

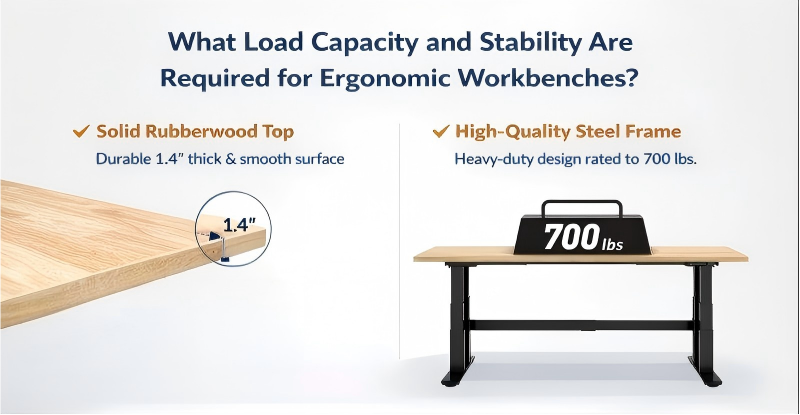

What Load Capacity and Stability Are Required for Ergonomic Workbenches?

Long-shift warehouse operations often involve repetitive handling of heavy items. An ergonomic workbench must remain stable under load to prevent micro-movements that contribute to fatigue.

Key considerations include:

- High static and dynamic load capacity

- Reinforced steel frames and cross-bracing

- Minimal flex during repetitive tasks

A stable work surface reduces muscle tension caused by constant posture correction. This is why many facilities favor heavy-duty ergonomic workbenches rather than lightweight tables originally designed for short-duration use.

Which Warehouse Tasks Benefit Most from Ergonomic Workbenches?

Ergonomic workbenches provide the greatest impact in long-shift warehouse tasks such as:

- Packing and shipping stations with continuous box handling

- Assembly and kitting areas requiring precision and repetition

- Quality inspection tasks with static posture demands

- Repair and maintenance workstations with mixed tool usage

In these environments, ergonomics directly influences both speed and accuracy. Workstations designed for adaptability allow operations to scale without increasing physical strain.

Are Ergonomic Workbenches Worth the Investment?

From an operational perspective, ergonomic workbenches are not a luxury—they are a risk management tool.

Warehouses using ergonomic workstation designs often report:

- Reduced injury-related downtime

- More consistent productivity across long shifts

- Lower employee turnover

- Improved quality and accuracy

When evaluated over multiple years, ergonomic workbenches typically deliver measurable returns through labor efficiency and reduced health-related costs.

Final Checklist: How to Choose an Ergonomic Workbench for Long-Shift Warehouse Operations

- Does the workbench support height adjustability?

- Is the surface size appropriate for the task and reach zones?

- Can it handle continuous heavy-duty use without flex?

- Does it integrate accessories such as shelves, monitor arms, or footrests?

- Is it designed specifically for industrial warehouse environments?

Selecting the right ergonomic workbench is a long-term decision that directly affects warehouse performance, safety, and workforce sustainability.